用高清光纤感应验证复合弹簧设计(HD-FOS)

2015年7月的车辆动态国际杂志 - 在汽车悬架设计中提供复合材料的案例研究

在2015年7月期的车辆动力学International magazine, the author of the article ‘Lightest Touch’ asks if using composites within an automotive chassis is the key to achieving EU and US mileage targets. The article presents a case study of a light weighting program for the 2013 Peugeot 208 Hybrid FE, targeting a 20% reduction in vehicle weight. Peugeot achieved this goal in large part by focusing on substituting glass fiber resin composite materials for the steel used in the vehicle’s suspension systems. The suspension/chassis components represent a substantial percentage of vehicle weight exceeded only by the powertrain and body. Furthermore, the fabrication of suspension components from composite materials more easily align with the current state of composite manufacturing processes. Within the automotive industry, suspension systems and other chassis components may represent the low hanging fruit for the early adopters of composites.

在2015年7月期的车辆动力学International magazine, the author of the article ‘Lightest Touch’ asks if using composites within an automotive chassis is the key to achieving EU and US mileage targets. The article presents a case study of a light weighting program for the 2013 Peugeot 208 Hybrid FE, targeting a 20% reduction in vehicle weight. Peugeot achieved this goal in large part by focusing on substituting glass fiber resin composite materials for the steel used in the vehicle’s suspension systems. The suspension/chassis components represent a substantial percentage of vehicle weight exceeded only by the powertrain and body. Furthermore, the fabrication of suspension components from composite materials more easily align with the current state of composite manufacturing processes. Within the automotive industry, suspension systems and other chassis components may represent the low hanging fruit for the early adopters of composites.

从传统金属转换到复合材料 - 挑战和未知数

由于能够提供高强度 - 重量比,复合材料在军事和商业航空航天领域获得了显着的牵引力。188金宝搏软件然而,在航空航天中的复合材料引入并未有问题,并且在许多方面,航空航天188金宝搏软件行业仍然存在于学习曲线上。汽车行业的设计师需要意识到复合材料的各向异性和异构特性限制了已发布的材料属性数据的可用性。如果没有这种数据,工程师无法再确定计算机辅助工程(CAE)和其他仿真工具将提供组件性能的准确预测。复合材料为制造业提供额外的挑战,工程师需要确保部分易变度良好地理解和控制。在航空航天行业中,通过188金宝搏软件采用用于复合结构的试验和验证方法的新技术,通过采用新技术来解决复合材料所带来的挑战。来自Luna的高清晰度光纤感应(HD-FOS)是各级航空航天价值链中使用的关键测试和验证技术。188金宝搏软件

用HD-FOS仪表复合部分 - 实现应变计不可能的完整场地视图

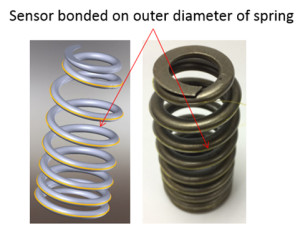

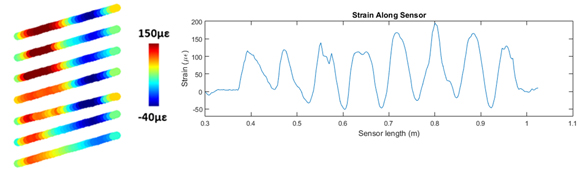

拉紧gages are the traditional method of measuring strain on springs. This method of point sensing is very limiting as there are only so many strain gages that can be mounted to a spring. Each strain gage needs to be individually wired and provides just a single strain measurement for every location instrumented. By contrast a single HD-FOS sensor can be mounted along the entire length of a spring and provides strain measurements in increments of one millimeter. This method of measuring strain of springs offers simplicity of instrumentation as well as a full characterization of the strain profile simply unobtainable with any other method. Figure 1 shows a steel helical spring instrumented with an HD-FOS sensor. The sensor bonding method is similar to that used by strain gages. Figure 2 shows the data taken from a single HD-FOS sensor mounted on the helical spring when in compression. The color-mapped image shows a 2D visualization of the strain profile; the strain vs length plot shows the high definition strain measurements along the length of the spring. The advantage offered by HD-FOS as compared to one, two, or even a dozen individual strain gages is very clear and this advantage compounds as component designs move away from metals and toward new advanced composite materials.

In summary – HD-FOS in automotive, benefiting from the experience of aerospace

在汽车行业中采用复合材料是暂停系统的何时,而不是悬架系统的制造商可能是复合材料的早期采用者。汽车行业可以从航空航天的经验中学习,包括在测试由复合材料制成的部件和结构时使用高清FOS感应。188金宝搏软件在航空航天工业188金宝搏软件中,HD-FOS在所有级别的价值链中使用;从对大型组件的结构测试的表征表征新材料的行为。HD-FOS非常适合揭示与复合材料相关的应变梯度和其他不协调以及伴随其使用的新加工,紧固和加入方法。

要了解有关Luna的Odisi如何使用HD-FOS与您的应用程序合作的信息,请单击这里。