TeraMetrix Explores Off-line Terahertz (THz) Measurements of Bottle and Preform Layers

Manufacturers use both on-line process control measurements, and off-line quality control measurements. The off-line measurements are typically those that take additional time, but often show detail that cannot be obtained on-line. More in-depth study early in the process can actually decrease the setup time (possibly by days) for the manufacture of a new product and help characterize product specifications (e.g., wall thickness) and effectiveness of new materials (alternatives to plastics).

Off-line measurements and optimization methods can be quite varied often providing more detailed measurements or analyses that can be used to improve the product or improve the process. An example is the fast (< 40 sec) generation of whole bottle thickness maps for total and individual layer thicknesses in a multi-layer structure. The current method requires time consuming destructive measurements at only a few places on the bottle. However, aT-Ray 5000Terahertz测量系统以1 kHz展开在线或离线,可以提供完整的瓶子详细信息,以显着缩短这些复杂多层瓶的启动周期,并提高产品的层厚度一致性。188金宝慱官网

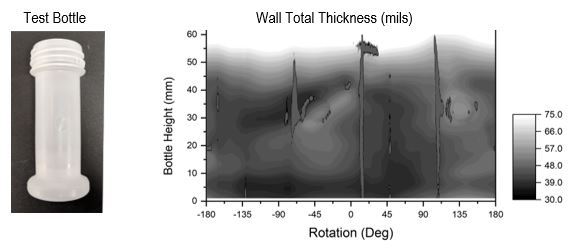

在此处的示例性情况下,将多层瓶放置在可以沿瓶子的长度旋转并平移的Z-θ旋转级上。然后可以映射总壁厚,以及每个单188金宝慱官网独的层。

Certain areas of the bottle do not provide a measurement, e.g. along seams and highly curved injection points. In the image above, the cylindrical section of the bottle is mapped in this way. The entire scan took approximately 40 seconds, but this is dependent on the resolution required.

对于具有188金宝慱欢迎你关键结构的产品(例如,制药瓶中的屏障层和燃料箱),确认结构的存在和适当的制造是必不可少的。内部阻挡层的缺失或厚度不足可能是非常有问题的。188金宝慱官网现货检查是一种常见的做法,但全部产品扫描既可以用于质量QA目的和产品优化/成本节约目的。在不需要任何耦合剂的情况下,常规且容易地使如此全部扫描这种整体产品的能力,并且测量透明和不透明材料进一步增加了测量值。

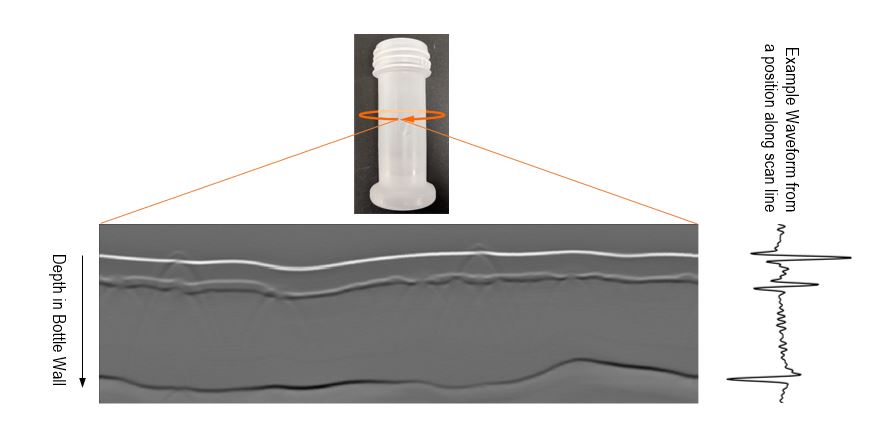

Even very quick (1 – 2 seconds) simple scans can provide a quite complete picture of the product. A simple linear scan of an object creates a B-Scan which is a cross-sectional image of the product along the scan line. The image result can clearly reveal improper layer structure. For example, a scan line can be the circumference around the round bottle. The B-Scan image demonstrates variations in total and individual layer thickness values along the scan line.

图像中的线的灰度对应于沿扫描线的波形中的反射峰的极性和幅度。B扫描的Y轴是波形的时间,其对应于瓶壁中的深度。

除了厚度变化之外,可以看到诸如188金宝慱官网中心阻挡层中的潜在间隙的附加特征。

A similar offline application of THz is the measurement of preforms used in blow molding, especially the detection of internal layers. One of the layers in a preform, with the addition of Carbon Black, can serve as a light blocking layer. It is critical that the layer extend up under the cap. THz is sensitive to Carbon Black due to the slight conductivity of the material which causes reflections of the THz pulse.

对预制件的重要测量是确认黑层在样品周围的所有360度到螺旋帽端足够远。对于如下图所示的样品,可以看出,黑层存在于下脊(绿色箭头)下方的两个位置,但不在脊(红色箭头)上方的两个位置处。

A B-Scan (cross section view) along the circumference of the preform at the heights of the Green and Red arrows help demonstrate the presence or absence of the Black layer.

在B扫描中,图像顶部附近的亮白线是预制件的外表面。底部附近的深色固体黑线是内表面。这些之间的较低强度光/暗线是内层的反射。

注意,对于绿色箭头位置的扫描,内部反射可以被视为白色顶线和黑色底线之间的清晰分层结构。

However, for the full scan at the Red arrow, the consistent layer structure can only be seen for the beginning and end of the image. The loss of the layer structure between these two areas means the Black layer does not extend up to the Red arrow position for all 360º of the sample.

这种类型的THz测量,由此启用T-Ray 5000and accompanying motion hardware, is a powerful tool for the examination and evaluation of both bottles and preforms. By measuring a bottle in this manner, the manufacturer can more quickly optimize a new production line, but also maintain a high quality product in ongoing production.