Creating Accurate Temperature and Sensing Measurements for Nuclear Reactors

Recently, Luna worked with Ohio State University (OSU) and University of Pittsburgh on a project - featured in the U.S. Department of Energy’sAdvanced Sensors and Instrumentation Sept 2020 newsletter- to help create accurate temperature and sensing measurements for nuclear reactors with the goal of making clean, nuclear energy a reality.

Governments around the world are facing a challenge: figure out how to meet an ever-increasing demand for electricity while also working to diminish the global dependence on fossil fuels. As a result, there is a growing need for sustainable forms of renewable energy. In conjunction with solar, wind, hydro, biodiesel, and ethanol, the U.S. government wants to build additional nuclear reactors to meet its energy demand. However, in order to ensure public health and safety, as well as to maintain energy security, the use of new nuclear reactors requires further research and development before being implemented on a broad scale.

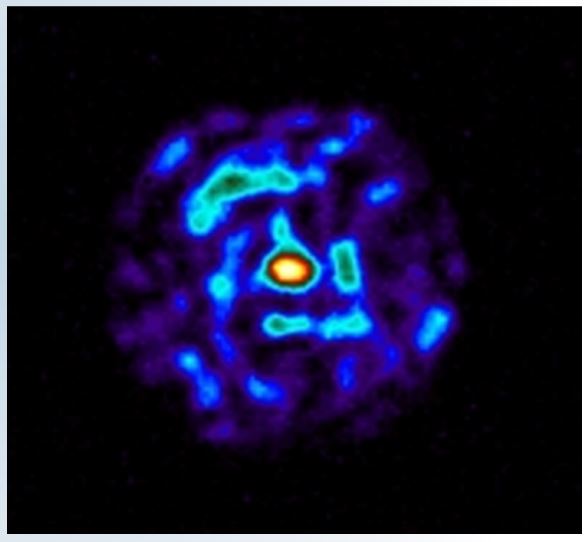

Driving the research and development for safer and more efficient nuclear reactors is an international task force, Generation IV. Gen IV’s design initiative features high-temperature reactors which are preferred due to the high amount of hydrogen they are able to produce without producing additional CO2However, they require in-core fuel and coolant temperature measurements for safe and efficient use. Currently, no low-drift temperature measurement technology exists. According to the project findings, highly accurate measurements are imperative for identifying hot spots, controlling thermal cycles, and performing temperature compensation of other sensors. Likewise, such measurements are needed to detect temperature spikes which, if missed, have the potential to result in premature failure of the reactor pressure vessel, fuel modules, containment breach, and possible product release.

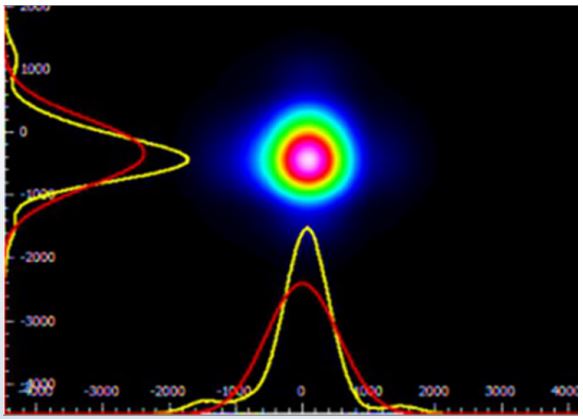

Together with OSU and Pitt, Luna hopes to develop the first commercial grade Single-Mode Sapphire Fiber (SMSF) sensors capable of operating in a high-radiation nuclear environment. The design of these sensors will provide more accurate measurements than their existing electrical-based substitutes. The SMSF sensor will have no electrical components within the reactor core, mitigating significant measurement drift, increasing sensor survivability, and eliminating the risk of the electronics shorting. The results of Phase I of the project were promising and excellent sensing performance was noted. The next phase will focus on researching factors such as how to optimize the performance of the SMSF sensor and develop production methods to minimize production costs.

Read the full article in the newsletterAdvanced Sensors and Instrumentation